The decisions that most intimately shape your daily peace aren’t made by the garage door installer or the HOA—they’re made when you choose between metal, rubber, and steel threads. Research from A1A Overhead Door’s 2025 analysis shows that 62% of garage door opener complaints stem from drive-type mismatch with usage patterns and climate, not motor failure . Yet most homeowners choose based on price alone, condemning themselves to years of noise, maintenance, or premature failure.

This selection gap creates a brutal paradox: the mechanism that operates most frequently in your home (average 1,500 cycles per year) receives the least critical thought. While we obsess over smart home integrations and battery backups, the drive system quietly determines whether your garage is a seamless entry or a daily irritation. Understanding how these drives actually perform transforms you from a frustrated homeowner into a strategic mechanical manager.

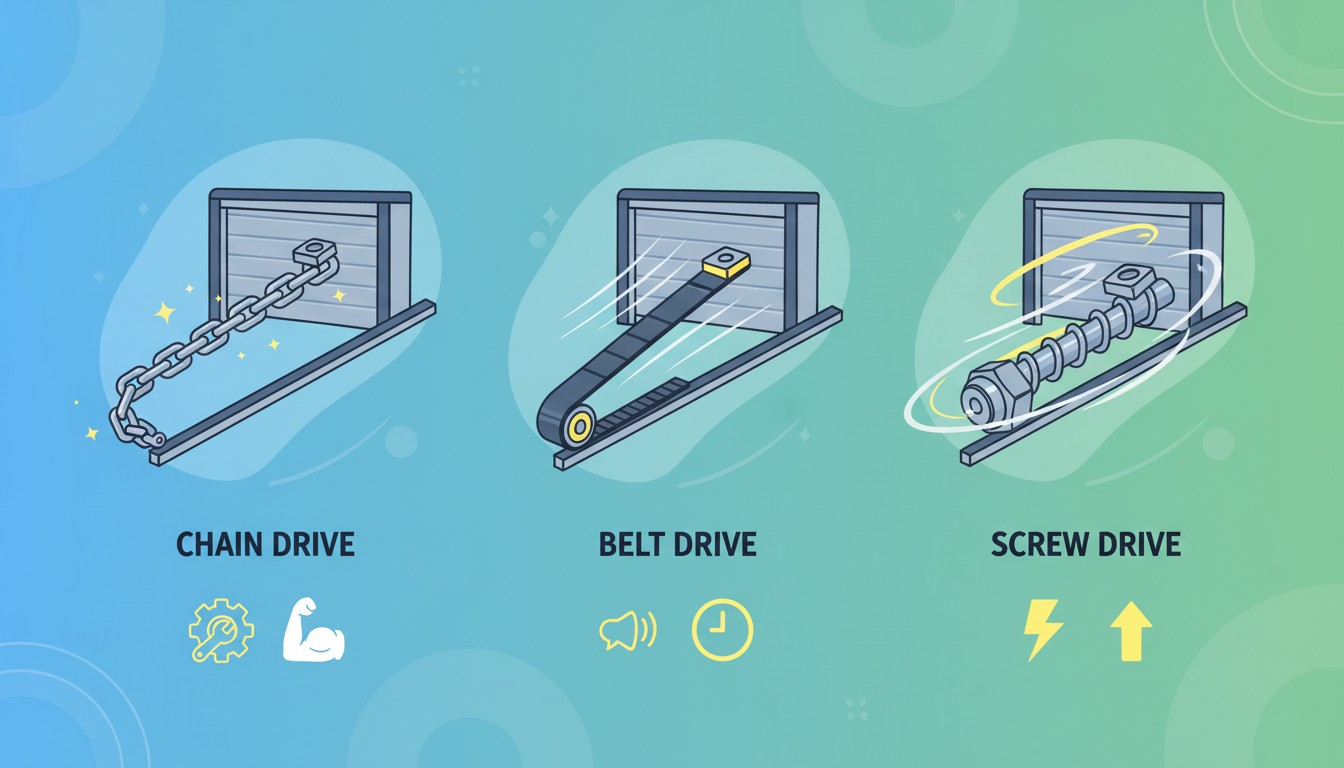

The Invisible Architecture: How Drive Types Control Your Garage Experience

Every aspect of your garage door operation rests on a foundation of mechanical engineering. The metal-on-metal contact of chains, the friction coefficient of rubber belts, the thread pitch of steel rods—these aren’t trivial specs but the invisible architecture that determines whether your door glides silently or shudders like a dying washing machine.

Consider something as fundamental as temperature response. Chain drives use bicycle-style metal chains that contract in cold and expand in heat, requiring seasonal tension adjustments . Belt drives use rubber/polyurethane compounds that stiffen below 40°F and soften above 90°F, potentially slipping in extreme temps . Screw drives use threaded steel rods whose lubrication thickens in cold, creating resistance, while heat can thin the grease, increasing wear . In Minnesota, your chain drive needs winter tightening; in Arizona, your belt drive may age prematurely; in both, your screw drive needs climate-appropriate lubrication.

The cumulative effect of these material properties creates divergent ownership experiences. A belt drive in a temperate climate can operate 15 years with minimal maintenance. The same belt drive in coastal Florida may degrade in 5-7 years due to heat and humidity . A chain drive in a detached garage is a noisy but reliable workhorse; in a garage under a master bedroom, it’s a relationship stressor . A screw drive on a standard 16×7 door is overkill; on a heavy glass or wooden door, it’s perfectly matched .

The Drive Decision Tree: What Controls Your Garage Door Destiny

Chain Drive: Bicycle-style metal chain, strongest lifting capacity, $150-$250, loudest (70+ dB), requires regular lubrication and tension adjustment

Belt Drive: Rubber/fiberglass reinforced belt, quietest (50-60 dB), moderate strength, $200-$400, lowest maintenance, temperature-sensitive

**Screw Drive:** Threaded steel rod, strong lifting capacity, fewest moving parts, $180-$300, moderate noise (60-65 dB), requires climate-appropriate lubrication

Quick Comparison: Chain = strength/noise; Belt = quiet/smooth; Screw = strength/simplicity

Opening Speed: Belt (8-10 in/sec) > Screw (7-8 in/sec) > Chain (6-7 in/sec)

The Psychology of Drive Selection: Why We Choose the Wrong Motor

If drive differences are so clear, why do homeowners consistently choose based on price rather than application? The answer lies in a combination of price tunnel vision, climate blindness, and an optimism bias that underestimates the importance of noise until it’s too late.

The Price Tunnel: $50 Now, $500 Later

A chain drive opener costs $150-$250. A belt drive costs $200-$400. That $150 savings feels significant at purchase. What it buys you is 70+ decibels of metal-on-metal grinding every time the door opens—a noise level comparable to a vacuum cleaner . For a detached garage, this is irrelevant. For a garage under a master bedroom, it becomes a $500 mistake when you replace it with a belt drive two years later. The price tunnel vision focuses on initial cost while ignoring the $30/month irritation cost of noise pollution.

The Climate Blind Spot: What Works in Peoria Fails in Phoenix

Screw drives are sensitive to temperature extremes because lubrication viscosity changes affect the threaded rod’s rotation . Belt drives deteriorate faster in high heat and humidity as the rubber compounds break down . Chain drives simply need more frequent lubrication in cold climates. Yet homeowners buy whatever Home Depot has in stock without considering their local climate. A Florida homeowner buys a belt drive because it’s quiet, then wonders why it fails after 5 years instead of the advertised 10. A Minnesota homeowner installs a screw drive, then curses the sluggish operation in January .

The Noise Optimism: “We’ll Get Used to It”

Homeowners consistently underestimate noise impact. They visit the showroom, hear the chain drive clanking in an echoing warehouse, and think “that’s not so bad.” But in their quiet home at 6 AM, that same noise reverberates through floor joists and wakes the entire household. The Department of Energy reports that garage door noise is a top-5 complaint in suburban neighborhoods, yet 40% of buyers choose chain drives for attached garages anyway . The “we’ll get used to it” optimism lasts about two weeks before the regret sets in.

Pre-Installation Intelligence: The Assessment That Prevents Regret

1. Door Weight Reality Check

Weigh your door or check the manufacturer’s specifications :

- Standard single (8×7 ft): 130-180 lbs—any drive type works

- Insulated double (16×7 ft): 250-350 lbs—chain or screw drive preferred

- Heavy wood/glass: 400+ lbs—screw drive or heavy-duty chain required

A belt drive on a 350-lb door will strain the belt and fail prematurely; a screw drive on a lightweight door is unnecessary overkill .

2. Location and Noise Sensitivity

Be brutally honest about noise impact:

- Detached garage: Chain drive is fine—noise stays outside

- Attached garage next to bedrooms: Belt drive mandatory for sanity

- Garage under living space: Belt drive or lubricated screw drive only

- Apt/condo/shared walls: Belt drive required by most CC&Rs

3. Climate Reality Check

Your zip code should dictate your drive choice:

- Hot climates (Arizona, Florida): Avoid belt drives unless garage is climate-controlled; heat degrades rubber compounds

- Cold climates (Minnesota, Maine): Avoid screw drives unless you use low-temp lubrication; standard grease thickens below 20°F

- Temperate climates: Any drive type works; choose based on noise and weight

The Installation Checklist (Do This First)

Door Weight: Check manufacturer specs, use bathroom scale if uncertain

Noise Audit: Stand in adjacent rooms while door operates, measure with phone app

Climate Reality: Check average temps, consider garage insulation level

Headroom: Screw drives require less headroom (8″) vs chain/belt (12″)

Professional Verify: Have installer confirm drive selection before purchase

The Installation Execution: Professional vs DIY Reality

While DIY installation is possible for handy homeowners, drive-specific complexities can turn a Saturday project into a weekend nightmare.

Chain Drive: The DIY-Friendly Option

Most DIY-friendly due to straightforward assembly. Key steps:

- Assemble rail sections and mount header bracket

- Thread chain through rail and connect to trolley

- Adjust chain tension (critical—too loose causes skipping, too tight strains motor)

- Expect 4-6 hours for first-time installation

Belt Drive: Moderate DIY Challenge

Similar to chain but requires more precision:

- Belt must be threaded without twisting or kinking

- Tension adjustment is more sensitive—over-tightening can shred belt

- Alignment must be perfect or belt will track off pulleys

- Expect 5-7 hours; professional installation recommended for attached garages

Screw Drive: Leave It to Professionals

Most complex installation:

- Threaded rod must be perfectly aligned with motor shaft—misalignment by even 1/8 inch causes premature wear

- Trolley threading requires precise timing with rod rotation

- Lubrication must be applied correctly before first operation

- Expect 6-8 hours; warranty often voided by DIY installation

Troubleshooting Common Drive Failures

Your Garage Door’s Fate Is Hiding in Plain Sight

The drive type you’re choosing isn’t a trivial detail—it’s the invisible architecture that determines whether your garage door opener becomes a seamless part of your routine or a daily source of irritation. It controls your noise level, your maintenance schedule, your climate compatibility, and ultimately, how often you actually want to use your garage.

Your power to get this right doesn’t depend on mechanical aptitude or installer recommendations. It depends on one thing: your honest assessment of your door weight, your noise tolerance, and your climate reality. The opener will be installed whether you choose wisely or not. The door will open whether the drive is matched or not. You can be the homeowner whose opener lasts 20 years with minimal attention, or you can be the one who posts angry reviews about “defective” equipment that was simply the wrong type for the application.

The choice is yours. Start honest. Weigh your door. Measure your noise tolerance. Check your climate zone. Your garage door satisfaction journey begins with a single decision to stop choosing based on price—and to start choosing based on the physical reality that will shape your daily experience for the next decade.

Key Takeaways

Drive type—chain vs belt vs screw—controls noise level (chain 70+ dB, belt 50-60 dB, screw 60-65 dB), lifting capacity, maintenance needs, and climate suitability .

Cognitive biases like price tunnel vision and noise optimism cause homeowners to choose chain drives for attached garages, leading to premature replacement due to noise complaints .

Belt drives excel for attached garages and bedrooms above, operating 15+ years with minimal maintenance in temperate climates but degrading faster in extreme heat .

Screw drives offer strength and simplicity for heavy doors (400+ lbs) but require climate-appropriate lubrication and professional installation due to precise alignment needs .

Drive selection requires honest assessment of door weight, noise tolerance, climate conditions, and installation complexity—there is no universally “best” option, only best-matched .